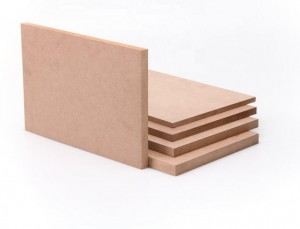

Special structure non-defrmation blockboard for Wardrobe door

Product Parameters

|

Core |

block board, plywood ,OSB |

| Veneer | PET or HP |

|

Glue |

Melamine glue or urea-formaldehyde glue Formaldehyde emission reaches the highest international standard (Japan FC0 grade) |

|

SIZE |

1220x2440mm |

|

THICKNESS |

18mm,20mm,22mm Special specifications can be customized according to user needs |

|

MOISTURE CONTENT |

≤12%, glue strength≥0.7Mpa |

|

THICKNESS TOLERANCE |

≤0.3mm |

|

LOADING |

8pallets/21CBM for 1x20’GP18pallets/40CBM for 1x40’HQ |

|

USAGE |

for furniture, cabinets, bathroom cabinets |

|

MINIMUM ORDER |

1X20’GP |

|

PAYMENT |

T/T or L/C at sight. |

|

DELIVERY |

about 15- 20days upon receipt of the deposit or L/C at sight . |

|

FEATURES |

1.Product structure is reasonable, less deformation, flat surface, can paint and veneer directly. wear-resisting and fire-proof.2.can be cut into small size for reusing |

plywood offers several advantages, including

Strength and Durability: Lay-up plywood is made by gluing multiple layers of thin wood veneers together, with each layer's grain direction oriented perpendicular to the layer below it. This construction makes the plywood stronger and more durable than solid wood, which can be susceptible to warping, cracking, and splitting over time.

Resistance to Moisture: Lay-up plywood has good resistance to moisture and is less likely to swell or warp in humid conditions. This makes it a good choice for use in areas with high humidity, such as bathrooms and laundry rooms.

Customizable: Wardrobe doors made from lay-up plywood can be cut and shaped to fit almost any size and shape of the closet. This allows for a greater range of customization and design options.

Cost-effective: Plywood is generally less expensive than solid wood and can provide a more cost-effective option for creating wardrobe doors.

Sustainability: Plywood is a sustainable material because it is made from renewable resources, and the manufacturing process uses less energy and produces less waste than other materials. Additionally, many plywood manufacturers use eco-friendly glues and adhesives to reduce their environmental impact.